By Steve Voynick

Editor’s Note: After you enjoy Part I of this fascinating topic, we invite you to check out Part II >>>

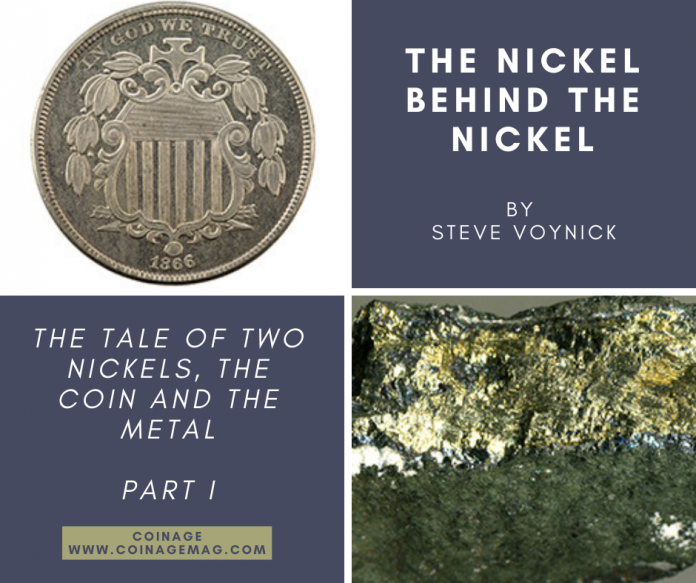

Nickel is a textbook example of a homonym. It can refer to our five-cent coin or the metal. And in U.S. coinage, the story of the two nickels—the coin and the metal —are interrelated. Nickel is the least familiar of the major circulating-coinage metals, past or present. While the histories and properties of gold, silver, and copper are widely known, that is not the case with nickel. Yet behind nickel’s relative obscurity is an unusual story—and some impressive coinage credentials.

Nickel was first used in coinage in antiquity, then not again for 2,000 years. Since it reemerged in the 1857 U.S. Flying Eagle cent (patterns struck in 1856), nickel has lent its name to the five-cent coins of the U.S. and Canada, provided a different look for much of the world’s circulating coinage, and evolved from a laboratory curiosity to a major industrial commodity.

(Wikimedia Commons)

The nickels, dimes, quarters, and half dollars in our pockets and purses today contain between 8.3 and 25 percent nickel. To produce these coins, the U.S. Mint uses about 4,400 tonnes (metric tons) of nickel per year. A lustrous, silvery-white metal with a slight golden tinge, nickel is as dense as copper and has a substantially higher melting point. It is much harder and less workable than gold, silver, or copper. And nickel, along with iron and cobalt, are the only three elements that exhibit strong magnetic properties.

NICKEL’S AVAILABILITY

Nickel is the fifth most abundant element on Earth; most of it, however, is in metallic form and combined with iron in the Earth’s core. In the Earth’s crust, where nickel occurs mainly as oxide and sulfide minerals, it ranks 28th among the elements in abundance, about the same as copper. Nickel is mined from two types of ores: surface deposits of laterite, a mix of iron and nickel oxides, and underground deposits of nickel-sulfide minerals.

Although metallic nickel is rare in the Earth’s crust, it is common in meteorites. Tools and weapons of exceptional quality were fashioned from meteoritic iron-nickel alloys as early as 3500 BCE. Around 1700 BCE, the Chinese began smelting nickel-rich copper ores to produce “white copper,” an alloy similar to today’s 75-25 copper-nickel (cupronickel) alloy. This use of nickel was unintentional, as early Chinese metallurgists believed that white copper was simply an unusual type of copper.

Nickel first appeared in coinage in the Greco-Bactrian kingdom, the easternmost part of the Hellenistic world, around 190 BCE. These cupronickel coins, comprised of a white-copper-like alloy that likely came through trade with China, were produced for only about 30 years. Nickel appeared again in the historical record when medieval miners in the Erzgebirge (Ore Mountains) along the present-day Germany-Czech Republic border encountered a reddish mineral that they assumed erroneously was a copper ore. These miners blamed their inability to extract copper on nickel, a goblin of German mythology, who had “cursed” the ore. They named the ore Kupfernickel, literally “copper goblin,” from the German word Kupfer for “copper.”

(Wikimedia Commons)

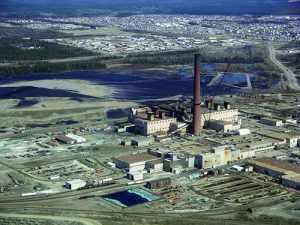

Scientists didn’t begin to unravel the mysteries of nickel until 1751. Swedish mineralogist Alex Fredrik Cronstedt smelted Kupfernickel to obtain a previously unknown white metal that he named “nickel” after the goblin of myth. Four years later, Swedish mineralogist Torbern Bergman produced pure nickel to confirm the metal’s elemental status. Initially, the rare Kupfernickel ore was the sole source of nickel. It is known today as the mineral nickeline (nickel arsenide). Not that it mattered then, because the metal was nothing more than a laboratory curiosity with no practical uses. In the 1820s, metallurgists found that nickel could enhance certain desirable qualities of steel. In 1830, Britain began using small nickel quantities to produce cupronickel trading coins. Residents of Britain’s Malaya protectorates used the coins. Norway built the first commercial nickel smelter in 1850.

NORWEIGAN SMELTER DRAWS U.S. INTEREST

Among the individuals interested in the limited Norwegian production of nickel was James Ross Snowden, the director of the United States Mint. In the early 1850s, Snowden was facing problems with the U.S. large cent. Struck in various designs since 1793, the cumbersome 10.9-gram, 28-mm-diameter large cent, made of copper, had grown increasingly unpopular. Even more concerning, the high price of copper was making the cost of producing the large cent prohibitive.

To solve these problems, the Mint designed the Flying Eagle cent, a much smaller, 4.7-gram, 19-mm-diameter coin consisting of an innovative 88-12 copper-nickel alloy. In 1857, the first official issue of the Flying Eagle cent—17.4 million coins, the most massive annual production of any U.S. coin to date—used 9.8 tonnes of Norwegian nickel. The Indian Head cent composed of the same 88-12 cupronickel alloy replaced the Flying Eagle cent in 1859. Both coins became known as “nicks” because of their nickel content and as “white cents” for their lighter color than that of the large old cent.

To accommodate a new three-cent postal rate back in 1851, the Mint had introduced a three-cent coin with a 75-25 silver-copper composition. In 1865, to counter silver hoarding at the end of the Civil War, it replaced its silver-copper alloy with one of 75-25 cupronickel. This new coin was popularly referred to as the “three-cent nickel.” Also, in 1865, the Mint replaced the nickel in the Indian Head cent with copper, containing small amounts of tin and zinc. The following year, the Mint introduced the 5.0-gram, 75-25 cupronickel Shield five-cent coin, which became known as the “five-cent nickel.”

Just as the Mint stepped up its use of the cupronickel alloy, a domestic source of nickel suddenly appeared—the American Nickel Company of Camden, New Jersey, owned by Philadelphia industrialist Joseph Wharton. Wharton, who had profited handsomely from zinc mining and smelting in the 1850s, saw an opportunity in the U.S. Mint’s growing use of nickel. He began vigorously promoting cupronickel coinage through his political contacts in Washington,

D.C. while cautioning against excessive purchases of foreign nickel.

Not coincidentally, Wharton had acquired the Gap Mine near

(Wikimedia Commons)

Lancaster, Pennsylvania, in 1863. The Gap Mine had been worked for copper intermittently and with little success since 1718. In 1852, the Gap miners discovered nickel ore minerals millerite (nickel sulfide) and pyrrhotite (nickel-rich iron sulfide). But the subsequent effort to mine nickel had also failed, and the mine closed in 1860. Wharton bought the inactive mine at a bargain price, reorganized it as an efficient nickel-mining operation, and established a nickel refinery in Camden, New Jersey. And when the Mint began high-volume production of the cupronickel three-cent and five-cent coins, Wharton owned the only domestic nickel source.

In just three years, the Mint turned out 75 million Shield five-cent nickels that contained nearly 100 tonnes of nickel, then a substantial part of the world’s nickel supply. With all of it coming from Joseph Wharton’s enterprise. By the time the Gap Mine closed in 1893, it had yielded 2,250 tonnes of nickel. Much of the yield had gone into a quarter-billion Shield and Liberty Head nickels. Wharton used part of his hefty nickel profits to establish the University of Pennsylvania’s Wharton School of Business and help found the International Nickel Corporation (now Vale Limited).

If you enjoyed what you’ve read here we invite you to consider signing up for the FREE COINage Connection e-newsletter. Learn more>>>

In addition, we invite you to consider subscribing to COINage magazine. The cost for a one-year U.S. subscription (6 issues) is $24.95. Learn more >>>